Straw Bale Landscape Wall Construction

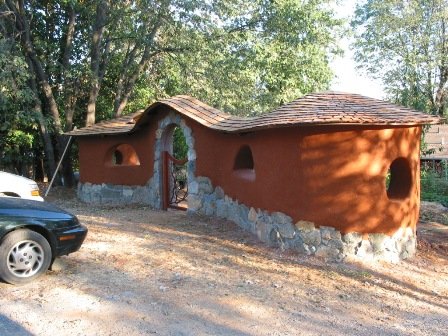

Do you live in a loud neighborhood? Are you tired of looking at the same style of wood fence around every home in your neighborhood? Building a straw bale landscape wall instead of a typical privacy fence around your garden may be a better choice. The straw bales not only provide privacy but also superior soundproofing. If you live on a busy street, near a loud school, or near the highway, you'll find the soundproofing qualities of a straw bale wall amazing. In addition to the privacy and soundproofing, straw bale landscape walls are beautiful. They are more elegant and original than any conventional landscape wall, be it wood, stone, or concrete block.

The natural undulations and curves also make straw bale walls more comfortable for the human experience. It may sound strange, but straw bale walls can actually help calm the people in your home. Studies have shown the calming effects of straw bale walls on horses and humans alike. It seems the natural beauty of straw bale walls is more than just pleasing to the eyes.

LANDSCAPE WALL HEIGHT

Straw bale landscape walls can be any height, although the taller they are, the harder they are to build and the more room they take up on the property. This is because buttress walls must be used to support the walls from wind loads and physical loads applied against them. These perpendicular loads, if not protected against, can bring a wall down in a flash.

A common height for a straw bale landscape wall is about 6 feet 8 inches tall. Smaller, roughly three feet tall walls can be created easily with no perpendicular supports. If you're looking for a simple accent for a backyard garden, the lower wall may be the way to go; however, if you want privacy and soundproofing, you're better off with a taller wall than you are. Otherwise, the sound and sights will still meet your eyes and ears above the top of the wall.

LANDSCAPE WALL FOUNDATION OPTIONS

The easiest and most "Green" permitable foundation system for under your landscape wall is a rubble trench foundation. (For more on Rubble Trench Foundations click here)

To get started, dig a 2-foot wide trench deep enough to get below the frost line. The trench should be at least two feet deep, no matter how shallow the frost line is. For example, in Portland, and most of Western Oregon for that matter, the frost line is very shallow at roughly 7-10 inches deep. Nonetheless, renting a backhoe is a good idea since your trench will bottom out at 2 feet deep.

Place a 3-inch perforated pipe at the bottom of the trench if your soils are high in clay or otherwise don't drain well. You don't want water filling up the space beneath the wall. Make sure the drain line "daylights" for proper draining. This means it needs to end somewhere above grade so that any water it collects can drain out and away from the wall. Be sure to wrap the pipe in landscape cloth or a "drain sock" to limit any fine dirt material from entering the pipe and blocking the flow.

Now get ready to move some rock! Fill the trench with rounded drain rock up to the last 4 to 6 inches below grade. The cool thing about drain rock is that you don't have to compact it for it to be stable. This eliminates a labor step and ensures that you don't crush your drainpipe with overly aggressive compaction.

It's a good idea to soak the trench with water as you add the rock. This helps everything settle into position. Before adding the bales, you'll need to create a bond beam or a concrete cap for several purposes.

CREATING YOUR BOND BEAM

The first purpose is to secure the top of the trench so that the loose drain rock cannot shift under the weight of the straw bale wall.

The second purpose is to provide lift for the bales above grade. You don't want the bales sitting at grade level, as moisture, grass, and other debris can contaminate the base of the wall.

Finally, the bond beam provides an anchoring point for your bale toe-ups. Toe ups are the wood at the bottom of the wall that once again lift the bales up, this time off of the concrete, which can otherwise wick water into the bales. Toe-ups also provide a nailing surface for a later step in the process.

To set the bond beam, place form boards above the lip of the trench so that the finished surface will be level and roughly 6 inches above grade. If you live on a sloping site, you can choose to slope the wall with the topography or build it level and include steps that add a bale height at a time. This is similar to residential foundation construction on steep terrain.

If you use a different sysetem, remember to raise the bales off the ground by at least 6”.

INSTALLING ANCHOR BOLTS

When the forms are complete, place anchor bolts appropriately to hold down the toe-ups. Remember that the toe-ups will be 4x4 pressure-treated wood, and you are required to have a bolt within the first foot of every board and every 6 feet along that board. Because the layout can be confusing, especially for someone not well-versed in construction, you may choose to install bolts after the concrete has been poured and finished. These bolts would be drilled into the dried concrete and can thus be easier to lay out and install. Consider using wedge bolts or Simpson EZ-Anchors.

Install the toe-ups on top of the foundation so that their outer edge fits flush with the outer edges of the bond beam on either side. It's important to note here that the 2-foot wide trench is based on using three-string bales, which are roughly 2 feet wide. If you plan to use two string bales, which are 18 inches wide, you'll need to adjust your trench width accordingly. Three-string bales are a little more stable for straight-wall construction and are more readily available in the Portland, Oregon, area.

STACKING YOUR BALES

With the toe-ups in place, you can start stacking your bales. Remember to stack them like Legos, alternating the joint location from row to row. Consider the pattern of a brick wall; that's what you are trying to achieve with the stacking pattern for the bales. Once your bales are stacked to the desired height, place a pond liner over the top of the wall. The liner should only extend over the top course of bales, so the sheet should be roughly 4" wider than the bales on either a 2 or 3-string bale wall. This simply helps protect the bales from rain.

INSTALL YOUR WIRE MESH

Finally, pull wire mesh over the wall. Attach it to the toe up on one side of the wall and stretch it up and over the wall to the other side. Attach it to the toe-ups on the other side of the wall. I prefer to use strong mesh here. My personal favorite is either 16 or 14-gauge welded wire mesh in a 2" x 2" grid. With the mesh in place, use a baling needle (plans for making your own needle are available for purchase here) and poly baling twine to sew the mesh through the bales.

Here’s an example of the baling twine type and strength we use for straw bale home construction. (paid link) You will want two needles, one on each side of the wall, to sew the mesh together quickly. Now, you're ready to plaster, but that's another story for another day.

Rain Protection

To protect the bales from rain, which is important, as you suggest, use either a metal fabricated cap (specially made) over the top of the wall or a pond liner draped over the top and down the sides about one bale course under the plaster.